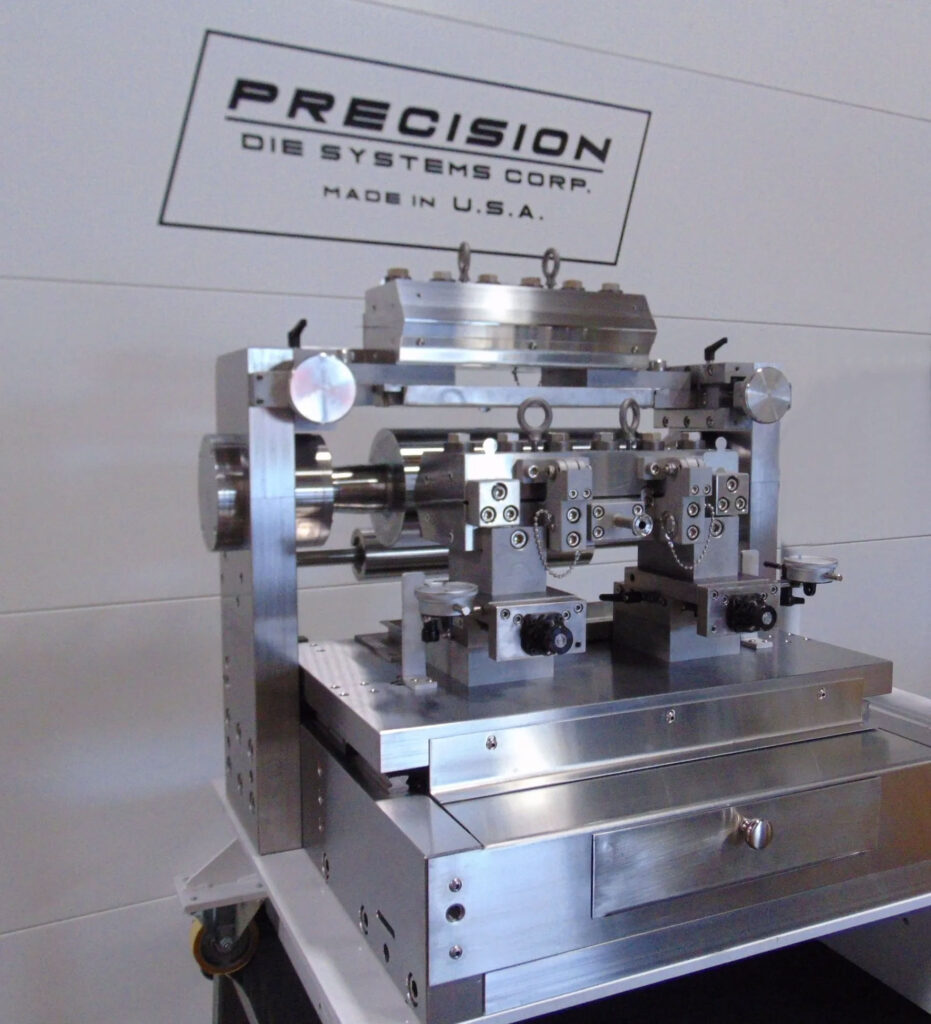

Fixed Slot Dies from Precision Die Systems

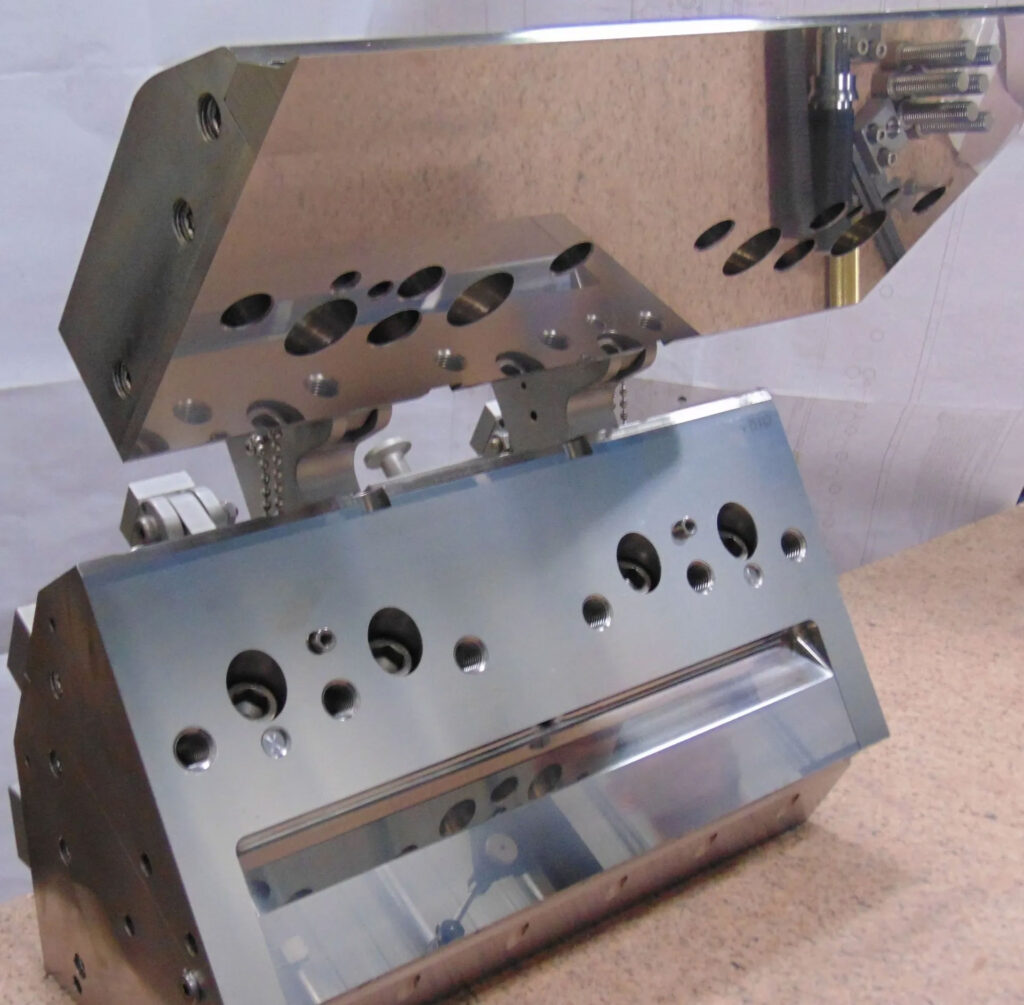

Precision Fixed Slot Dies coating technology is used to deposit a variety of liquid chemistries onto glass, stainless steel, and plastic substrates for the development and production of a broad range of applications. This is achieved through the precise metering of the process fluid and dispensing it at a controlled rate while the coating die is precisely moved relative to the substrate.

Precision Die Systems fixed slot dies technology allows for efficient, high performance spin-less coating for applications such as flat panel displays (including LCD, OLED, flexible, and others), photovoltaic panels (such as CIGS, CdTe, OPV, and others), Solid State Lighting (OLED and LED), and various Organic and Printed Electronic applications such as RFID, Lithium, Li-Ion, Fuel Cell, Battery Electrode Coating, Sensors and others.

Precision Die Systems Corporation is a total process and hardware resource for the coating industry.